what we do

We specialize in advanced metal forming techniques that cater to a variety of industries.

Our Process

Luxfer Superform specializes in a variety of forming techniques ranging from Cavity, Bubble, Diaphragm and Back Pressure forming.

Across all techniques, we use the following method:

- A metal sheet is clamped and heated in a hot press.

- Increased air pressure is used to force the sheet against a single-surface form die to provide the required shape.

- Part is subsequently trimmed and other value-added processes incorporated as required.

This process is derived from one of our core strengths, which is the unique design capabilities we possess for SPF. We strive to work with our customers during the design phase to ensure the desired end result

is accomplished. Whether it be from a multi-piece assembly turned into a single forming, to a weight reduction exercise, utilizing our SPF technology helps achieve an array of solutions for your needs.

All tooling is design engineered in-house, utilizing Catia V5-V6 as well as tool proofing through our Finite Element Analysis Software (PAM-STAMP) ensuring feasibility of parts before entering the press! This enables Superform to produce parts and minimize tooling costs at a fraction of the time and price compared to conventional tool stamping dies.

Our Capabilities

Luxfer Superform's equipment and process capabilities include:

- Computer controlled Superplastic Forming Presses

- CNC 5-axis machining centers

- Prima Industries Optima Laser Trim center

- Chemical Cleaning System

- Welding Operation

- Mirror Finish Polish

- Detail Product Assembly

- Skilled Metal Forming Craftmanship Techniques

- CATIA V5-V6 and Mastercam seats

- PAM-STAMP forming simulation software

- Inspection center including two 7-axis Romer arms utilizing Verisurf

- Horizontal Arm CMM

- AS9100, ISO45001, ISO9001 Certified

Leading manufacturer with proprietary technical knowledge

Developed over 50 years in high temp. superplastic formed complex sheet metal products and assemblies that other conventional processes cannot replicate.

Longstanding relationships and contracts with global OEM customers

Driven by long-term partnerships across commercial and military aerospace, space, transportation, and niche automotive markets.

aerospace Products

Waffle Structures

ATV Panels for Space Station

Waffle Structures

Lightweight, strong, and rigid structural components

Nacelle Panels

ATV Panels for Space Station

Waffle Structures

Streamlined aerodynamic covers for aircraft engines

ATV Panels for Space Station

ATV Panels for Space Station

ATV Panels for Space Station

Spacecraft panels for structural integrity

Winglet Transitional Fairing

ATV Panels for Space Station

ATV Panels for Space Station

Aerodynamic wing tip components for fuel efficiency

Automotive Products

Structural Inner Panels

Structural Inner Panels

Lightweight, strong, and rigid structural components

Fuel Tank Covers

Structural Inner Panels

Combines precision shaping with reduced weight for optimal performance in elite race cars

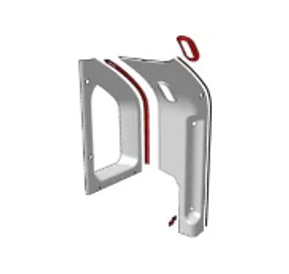

Outer Sill and Door Panels

Outer Sill and Door Panels

Unmatched design freedom and performance-driven styling

transportation and rail Products

Inner Door Pillars

Interior Window Rings

Interior Window Rings

Lightweight, high strength structural components

Interior Window Rings

Interior Window Rings

Interior Window Rings

Slim profile aluminum window sill tailored for next generation train design.

architectural Products

Refined Geometry

Individually Crafted

Individually Crafted

Perfect for architects seeking both aesthetic and structural performance

Individually Crafted

Individually Crafted

Individually Crafted

Complex curvature and seamless detail highlight the craftsmanship

Project Specific

Individually Crafted

Project Specific

Our process supports cutting-edge designs and structural integrity

Get started

Ready to bring your project to life? We're here to help. Contact us today for a personalized quote tailored to your specific needs.

Luxfer Superform

6825 Jurupa Ave, Riverside, California 92504, USA

Business: (951) 351-4100 Email: superformusa@luxfer.com

office Hours

Open today | 09:00 am – 04:00 pm |

Copyright © 2025, Luxfer Superform USA. All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.